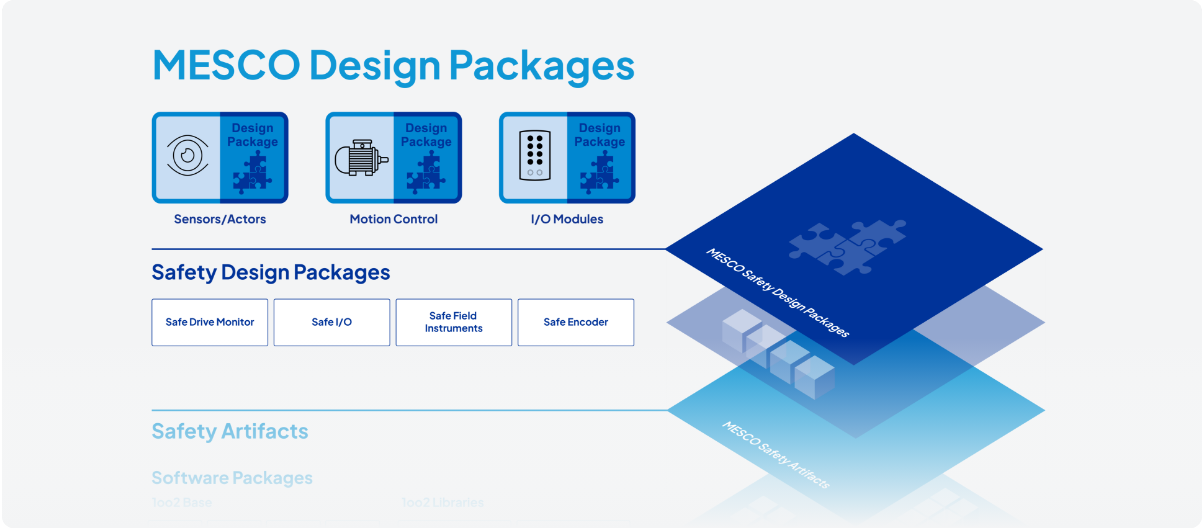

MESCO has developed the Safety Design Packages for developers of safety components in order to fulfil the requirements in the area of functional safety. These packages consist of tried-and-tested artifacts and modules that have emerged from fundamental and product-independent developments at MESCO. The MESCO developers provide support to ensure reliable and standard-compliant implementation.

Functional safety in automation components

As machine and system complexity increases and production becomes more flexible in line with Industry 4.0, the need for efficient, intelligent sensors and actuators as well as higher machine availability is constantly growing. Functional safety is increasingly being integrated into automation components in order to be able to react more flexibly to increasing requirements.

This has a significant impact on development methods, particularly with regard to compliance with strict standards such as IEC 61508 and ISO EN 13849. Efficient safety development platforms play a key role here, as they enable the reuse and adaptation of existing modules and artifacts. This reduces development time and costs, optimises the use of development resources, minimises errors and speeds up the certification process.

Application-specific safety design packages

The MESCO Design Packages are a comprehensive collection of over 120 reusable artifacts that provide developers with an efficient basis for their projects. All software artifacts have been subjected to a static code analysis and prepared for unit tests. Developed in accordance with the requirements of IEC 61508, the design packages can be seamlessly integrated into a V-model-based project structure.

The application-specific design packages consist of logically grouped artifacts that are tailored to specific product groups. This resulted in design packages for the following areas:

- Safe Industrial Communication (both secure fieldbuses and standard fieldbuses)

- Safe microcontroller cores (SIL2 1oo1/SIL3 1oo2)

- Safe power supplies

- Redundant input and output systems

- Safe encoder interfaces

- Safe drive functions such as safe stop or safe speed monitoring

Thanks to these design packages, automation components such as drives, cobots, actuators, gripping and handling systems, encoders, remote I/O, laser scanners, light barriers and many more can be developed in a customised, cost-efficient and targeted manner. Requirements for both SIL2 and SIL3 are covered.

Modularisation in development is absolutely essential

The evaluation boards are based on the design packages and enable the verification of architectural designs, the practical setup of device connections and the validation of feasibility. They are used to create proof-of-concepts or quick functional models without the need for proprietary hardware.

Current challenges, constantly changing requirements for new products and the lack of time and resources in many development departments clearly show that modularisation in development is essential. Once developed, artifacts can either be reused directly or adapted with minimal effort, which significantly increases efficiency.

MESCO Design Packages: Numerous advantages

The MESCO Design Packages offer a versatile development platform that is flexibly expandable, customisable, scalable and reusable. With this platform, various automation components can be customised and developed, all on a uniform basis. This not only saves time and costs, but also simplifies the handling of known microcontrollers, their tools and possible bugs. This simplifies pre-development, task allocation and documentation and leads to significant cost savings.

In numerous successful projects and the use of the development platform, MESCO has carried out customised embedded development projects for customers that serve as the basis for complete product families. MESCO is continuously updating and expanding the platform with new, innovative artifacts that meet current requirements, industry trends, standards and technological developments.

Support and development services

MESCO Engineering offers customised support for the implementation of assemblies using the Safety Design Packages. The co-operation usually starts with technical workshops, followed by the definition of system requirements and the development of safety concepts. The system is then built using evaluation boards for a proof-of-concept, followed by concept approval by a notified body such as TÜV. This structured approach helps to minimise the development risk considerably.

The benefits of the MESCO development platform withe design packages at a glance:

- Highly flexible solution for the development of functionally safe industrial products

- Simplifying the development of devices for factory and process automation

- Reduced development costs and project lead times with high product quality